Is your business bleeding resources? In today’s unforgiving economy, operations managers and business owners face a brutal truth: traditional models are too slow, too costly, and too wasteful. You’re pressured to deliver more, faster, with less.

The solution isn’t just working harder—it’s implementing the Lean Philosophy. Originating from Toyota, this proven system is the ultimate weapon against inefficiency, now transforming every industry from logistics to healthcare.

This isn’t theory. This is the practical playbook to unlock lasting value and operational excellence.

Why Lean Operations is Your 2026 Strategy

Lean isn’t a trend; it’s a management discipline centered on one core idea: Maximize customer value by systematically eliminating waste (time, inventory, motion, defects, etc.).

Companies like Amazon (rapid delivery), the NHS (reduced patient waiting times), and, of course, Toyota (minimal defects/inventory) have built empires on these principles. For your business, this means:

-

Lower Overhead Costs

-

Increased Flexibility & Responsiveness

-

More Engaged and Empowered Teams

5 Guiding Principles for Operational Excellence

As a leader, your focus must be on embedding these five steps into your culture:

-

🔍 Define Value (Customer-Centricity): Stop guessing. What does your customer truly value? Align every effort to deliver that, and nothing more.

-

🗺️ Map the Value Stream (Clarity): Visualize every step of your process, from idea to delivery. Where does work stop? Where are the delays? This separates value-add from pure waste.

-

🔄 Create Flow (Seamless Execution): Structure your processes so tasks and information move smoothly, eliminating bottlenecks, delays, and interruptions.

-

🎯 Establish a Pull System (Demand-Driven): Produce or act only when there is confirmed demand. Eliminate the cost and risk of overproduction based on shaky forecasts.

-

📈 Pursue Perfection (Continuous Improvement): Foster a Kaizen culture. Empower every employee, every day, to suggest and implement small, incremental improvements.

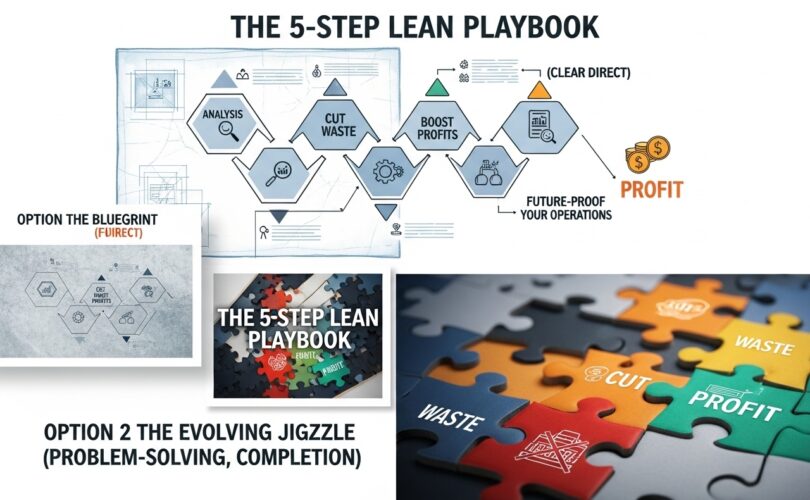

🔑 Your 5-Step Action Plan to Go Lean

Ready to start the transformation? Don’t attempt a massive overhaul. Focus on continuous, incremental change (Kaizen).

-

Value Stream Mapping: Chart your current processes meticulously. Highlight wasted time, resources, or budget. This diagnostic step is crucial.

-

Engage the Frontline: Involve employees at all levels in problem-solving. They are the experts in their own work—listen to their insights on what is broken.

-

Implement Kaizen: Prioritize small, low-risk, continuous improvements. This builds momentum and staff confidence without disruptive overhauls.

-

Standardize Success: Once an improvement is effective (e.g., a better meeting structure, a quicker sign-off), document it and roll it out across the organization to ensure consistency.

-

Monitor & Adapt: Track key KPIs (Lead Time, Defects, Cost). Review progress regularly and adjust your strategy. What gets measured, gets managed.

Leader’s Note: The Culture is the Catalyst

Remember, Lean is not a software package—it is a cultural shift.

-

Adopt Visual Management: Use Kanban boards or similar tools to make work-in-progress and priorities transparent.

-

Daily Stand-ups: Establish brief, focused routines for teams to coordinate and identify roadblocks.

-

Lead by Example: Leadership must consistently model and support the new behaviors.

Operational challenges are inevitable, but operational excellence is a choice. Embrace these principles, focus relentlessly on waste reduction, and empower your teams. Now is the time to start your Lean journey and drive genuine, lasting value.

What is the single biggest waste you see in your operations today? Share your thoughts below! 👇