Introduction

In today’s global economy, the traditional linear model of “take-make-dispose” is increasingly being challenged by the principles of the circular economy. This paradigm shift is driven by the need for sustainability, resilience, and efficiency in supply chain management. As noted by Ellen MacArthur, “The circular economy is a new way of designing, making, and using things within planetary boundaries.”

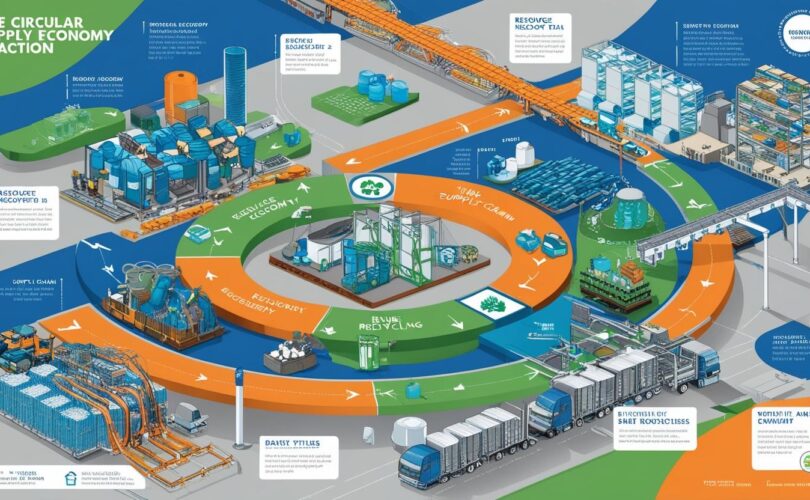

Key Principles of Circular Economy in Supply Chains

The circular economy is built around the 3Rs: Reduce, Reuse, and Recycle. This approach aims to maximize resource utilization by designing products and systems that minimize waste and optimize resource use.

– Design for Longevity and Recyclability: Products are designed to be long-lasting, easily recyclable, and repairable. This involves using predictive modeling techniques to enhance the durability and recyclability of products, thereby reducing the need for new raw materials.

– Closed-Loop Supply Chains: Materials and products are kept within the supply chain for as long as possible through recycling, part harvesting, remanufacturing, repair, refurbishment, and recommerce. This approach helps in retaining control over the lifecycle of products and materials, preventing resource loss and ensuring efficient reuse.

Benefits of Circular Economy Practices

Implementing circular economy principles in supply chain management offers several significant benefits:

– Increased Efficiency: By designing products and processes for ongoing value, companies can optimize storage, transportation, and other logistical processes. This circular approach ensures that resources are used to their fullest potential, reducing waste and enhancing overall efficiency.

– Cost Savings: The use of existing materials rather than new raw materials can significantly reduce costs. Additionally, careful tracking of resources and products can help in identifying areas where waste can be minimized, leading to cost savings in transportation and other areas.

– Improved Supply Chain Resilience: Circular supply chains are more adaptable and resilient to disruptions. By reducing dependency on scarce resources and component suppliers, manufacturers can maintain operations even amidst unforeseen disruptions, fostering sustainable growth and resilience.

– Reduced Environmental Impact: The circular economy helps in decoupling economic growth from resource consumption, reducing greenhouse gas emissions, and minimizing waste. This approach is crucial for tackling climate change and other environmental challenges.

Implementing Circular Economy Practices

Transitioning to a circular supply chain requires a fundamental reimagining of how products are designed, produced, and consumed.

– Audit and Strategic Vision: Manufacturers should start with a thorough audit of current practices and develop a strategic vision for circularity. This involves implementing pilot projects to test and refine circular initiatives.

– Technology Integration: The adoption of digital technologies such as the Internet of Things, Digital Product Passports, and Artificial Intelligence can enable transparent, efficient, and adaptable supply chains that support circular practices.

– Extended Producer Responsibility (EPR): Implementing EPR policies can hold companies accountable for the proper disposal of their products, encouraging the design of products with higher potential for recycling or reusability.

Role of Supply Chain Professionals

Supply chain leaders play a critical role in the transition to circular economy practices. They are responsible for sourcing, moving, and transforming materials within the global economy. By focusing on key areas such as raw material sourcing, supplier selection, manufacturing processes, and waste management, supply chain professionals can drive the adoption and scale of circular economy principles.

As Walter R. Stahel, a pioneer in the circular economy, once said, “The circular economy is not just about recycling; it is about designing products and systems that are restorative and regenerative by design.”

Conclusion

Embracing the principles of the circular economy offers a favorable strategy for sustainable supply chain management, yielding significant environmental and financial advantages. By integrating circular practices into the planning and operation of systems, companies can lower waste, diminish reliance on raw materials, and increase the effectiveness of resource usage. As the global business environment continues to evolve, adopting circular economy practices is not just a moral imperative but a strategic necessity for long-term success.

Promoting Sustainable Practices with Samunnati Ventures

At Samunnati Ventures, we specialize in guiding businesses through transformative changes, including the adoption of circular economy practices in supply chain management. With over 20 years of experience across various industries and global markets, our team is equipped to provide comprehensive consulting services that align your business strategies with sustainable and efficient practices. Contact us to learn how we can help your organization thrive in a circular economy.